الزنجبيلوهو من التوابل الثمينة والجذور الطبية، ويحتل مكانة هامة في التجارة والتصنيع العالميين. في مجال التصنيع بين الشركات (من شركة إلى أخرى)، يعد ضمان جودة الزنجبيل أمرًا بالغ الأهمية للحفاظ على سلامة المنتج وثقة المستهلك والامتثال التنظيمي. تتعمق هذه المقالة في الجوانب الحيوية لمراقبة جودة الزنجبيل، وتقدم رؤى ونصائح عملية للشركات المشاركة في إنتاجه واستخدامه.

لماذا تُعد مراقبة جودة الزنجبيل ضرورية في التصنيع بين الشركات

مخاوف الصحة والسلامة

تضمن مراقبة الجودة خلو منتجات الزنجبيل من الملوثات مثل المبيدات الحشرية والمعادن الثقيلة ومسببات الأمراض الميكروبية. يمكن أن تشكل هذه الملوثات مخاطر صحية خطيرة على المستهلكين، مما يؤدي إلى تداعيات قانونية ومالية محتملة على الشركات. إن ضمان سلامة منتجات الزنجبيل أمر بالغ الأهمية لحماية صحة المستهلك والحفاظ على معايير الصناعة.

الامتثال التنظيمي

تُعد مراقبة جودة الزنجبيل أمرًا بالغ الأهمية للوفاء بالمعايير التنظيمية التي وضعتها سلطات سلامة الأغذية. لا يضمن الامتثال لهذه اللوائح سلامة المنتج فحسب، بل يعزز أيضًا من سمعة الشركة وقابليتها للتسويق. فالهيئات التنظيمية في مختلف المناطق لديها متطلبات صارمة يجب الوفاء بها، ويمكن أن يؤدي عدم الامتثال إلى فرض عقوبات صارمة وسحب المنتجات وفقدان ثقة المستهلك.

ثقة المستهلك وسمعة العلامة التجارية

منتجات الزنجبيل عالية الجودة تبني ثقة المستهلك وولاءه. يمكن أن تؤدي المنتجات غير المتسقة أو ذات الجودة الرديئة إلى الإضرار بسمعة العلامة التجارية، مما يؤدي إلى خسارة المبيعات والحصة السوقية. ويتوقع المستهلكون الاتساق والموثوقية، كما أن تقديم منتجات الزنجبيل عالية الجودة باستمرار يساعد في ترسيخ هوية قوية للعلامة التجارية والولاء لها.

الكفاءة الاقتصادية

يمكن أن يؤدي تنفيذ تدابير فعالة لمراقبة الجودة إلى تقليل الهدر وزيادة كفاءة الإنتاج. من خلال اكتشاف العيوب في وقت مبكر، يمكن للشركات تجنب التكاليف المرتبطة بعمليات الاستدعاء وإعادة العمل. وتساعد عمليات مراقبة الجودة الفعالة في تحسين استخدام الموارد، وتقليل التكاليف التشغيلية، وتحسين الإنتاجية الإجمالية.

المكونات الرئيسية لمراقبة جودة الزنجبيل

1. توريد المواد الخام عالية الجودة

يبدأ أساس مراقبة الجودة بتوريد الزنجبيل عالي الجودة. ويتضمن ذلك اختيار الموردين ذوي السمعة الطيبة الذين يلتزمون بالممارسات الزراعية الجيدة (GAP) والتأكد من أن الزنجبيل الخام يفي بمعايير الجودة المحددة مسبقًا. ويمكن أن يساعد العمل عن كثب مع الموردين لفهم ممارساتهم الزراعية وإجراء عمليات تدقيق منتظمة في الحفاظ على جودة المواد الخام.

2. تنفيذ ممارسات التصنيع الجيدة (GMP)

تتضمن ممارسات التصنيع الجيدة مجموعة من الإجراءات والمبادئ التوجيهية لضمان إنتاج المنتجات والتحكم فيها باستمرار. وتشمل الحفاظ على نظافة المرافق، والمناولة السليمة للمواد الخام، والتدريب الشامل للموظفين. ويساعد الالتزام بممارسات التصنيع الجيدة في تقليل مخاطر التلوث ويضمن إنتاج منتجات زنجبيل آمنة وعالية الجودة.

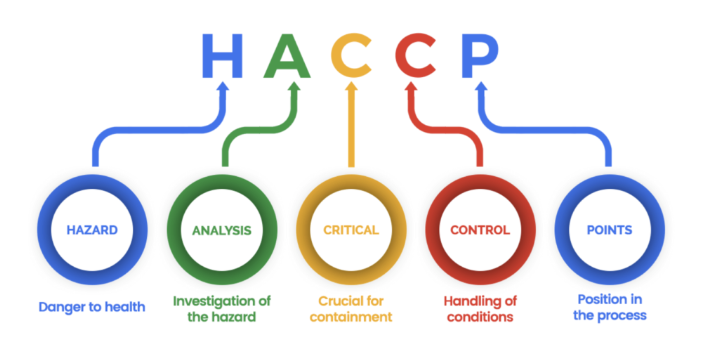

3. تحليل المخاطر ونقاط المراقبة الحرجة (HACCP)

نظام تحليل المخاطر ونقاط المراقبة الحرجة ونقاط المراقبة الحرجة هو نهج وقائي منهجي لسلامة الأغذية. ويحدد هذا النهج المخاطر المحتملة وينفذ تدابير التحكم في النقاط الحرجة في عملية الإنتاج. ومن خلال التركيز على الوقاية بدلاً من اختبار المنتج النهائي وحده، يساعد نظام تحليل المخاطر ونقاط المراقبة الحرجة في ضمان سلامة وجودة منتجات الزنجبيل في جميع مراحل سلسلة الإنتاج.

4. الاختبار والتحليل المنتظمان

من الضروري إجراء اختبارات منتظمة للزنجبيل للكشف عن الملوثات وسمات الجودة. ويشمل ذلك الاختبارات الميكروبيولوجية، وتحليل بقايا المبيدات، واختبار المعادن الثقيلة. ويضمن تنفيذ بروتوكول اختبار قوي تحديد أي مشكلات محتملة ومعالجتها على الفور، مما يحافظ على سلامة المنتج النهائي وجودته.

5. التصديق والامتثال

يمكن أن يؤدي الحصول على شهادات مثل العضوية والتجارة العادلة وISO 22000 إلى ضمان الجودة والسلامة. تتطلب هذه الشهادات الالتزام بمعايير صارمة وعمليات تدقيق منتظمة. وهي توفر طبقة إضافية من الثقة للمستهلكين والشركاء التجاريين، مما يدل على الالتزام بالحفاظ على معايير عالية الجودة.

عملية مراقبة الجودة في تصنيع الزنجبيل

عملية مراقبة الجودة خطوة بخطوة

1. فحص المواد الخام

- الفحص البصري: فحص العفن وتغير اللون والأضرار المادية.

- أخذ العينات: أخذ عينات للتحليل المختبري للتأكد من عدم وجود ملوثات والالتزام بمعايير الجودة.

2. التنظيف والتجفيف

- الغسيل: إزالة التربة والشوائب لمنع التلوث وضمان نقاء المنتج.

- التجفيف: التأكد من التجفيف المناسب لمنع نمو الميكروبات والحفاظ على جودة الزنجبيل ومدة صلاحيته.

3. الفرز والتصنيف

- الفرز: فصل الزنجبيل على أساس الحجم والجودة لضمان اتساق المنتج النهائي.

- التقدير: تصنيف الزنجبيل إلى درجات مختلفة بناءً على معايير الجودة، مما يساعد في تلبية متطلبات السوق المحددة.

4. المعالجة

- القطع والطحن: واعتماداً على متطلبات المنتج النهائي، تتم معالجة الزنجبيل في أشكال مختلفة مثل الشرائح أو المساحيق أو المستخلصات.

- التعبئة والتغليف: استخدام مواد من الدرجة الغذائية لمنع التلوث والحفاظ على جودة الزنجبيل أثناء التخزين والنقل.

5. الفحص النهائي للجودة

- الفحوصات المخبرية: إجراء التحليل النهائي لضمان الامتثال لمعايير الجودة والمتطلبات التنظيمية.

- إصدار الدفعة: الموافقة على الدفعة للبيع إذا كانت تفي بجميع معايير الجودة، مما يضمن وصول المنتجات عالية الجودة فقط إلى السوق.

الجدول: قائمة التحقق من مراقبة الجودة

| المرحلة | مقياس مراقبة الجودة |

|---|---|

| فحص المواد الخام | الفحص البصري وأخذ العينات للتحليل المخبري |

| التنظيف والتجفيف | الغسيل والتجفيف لمنع نمو الميكروبات |

| الفرز والتصنيف | الفرز حسب الحجم، والتصنيف حسب الجودة |

| المعالجة | التقطيع والطحن والتعبئة والتغليف في مواد صالحة للاستخدام في الأغذية |

| فحص الجودة النهائي | الاختبارات المعملية، والموافقة على إطلاق الدفعات |

فوائد المراقبة الفعالة لجودة الزنجبيل

يوفر تطبيق أنظمة قوية لمراقبة الجودة العديد من الفوائد:

1. تعزيز سلامة المنتج

يضمن أن منتجات الزنجبيل آمنة للاستهلاك، مما يقلل من خطر الإصابة بالأمراض المنقولة بالأغذية. من خلال منع التلوث وضمان معايير عالية، يمكن للشركات أن تقدم بثقة منتجات آمنة للمستهلكين.

2. تحسين رضا العملاء

تؤدي المنتجات عالية الجودة إلى إرضاء العملاء، مما يعزز الولاء للعلامة التجارية وتكرار الأعمال. ومن المرجح أن يوصي العملاء الراضون بالمنتجات للآخرين، مما يساهم في نمو الأعمال التجارية.

3. الامتثال التنظيمي

يساعد في تلبية المعايير التنظيمية المحلية والدولية، وتجنب المشاكل القانونية وحواجز الوصول إلى الأسواق. كما أن الامتثال للوائح التنظيمية يعزز مصداقية الشركة ويسهل العمليات السلسة في السوق.

4. كفاءة التكلفة

تقليل الهدر وإعادة العمل، مما يؤدي إلى توفير التكاليف وزيادة كفاءة الإنتاج. تساعد عمليات مراقبة الجودة الفعالة في تقليل الخسائر وتحسين استخدام الموارد، مما يساهم في الربحية الإجمالية للأعمال.

5. الميزة التنافسية

يمكن أن تحصل المنتجات المعتمدة وعالية الجودة على أسعار مميزة، مما يمنح الشركات ميزة تنافسية في السوق. كما أن معايير الجودة العالية تميّز الأعمال التجارية عن منافسيها، مما يجذب العملاء المميزين ويوسع نطاق وصولها إلى السوق.

نصائح للحفاظ على جودة الزنجبيل العالية في تصنيع B2B

1. الاستثمار في التدريب

تدريب الموظفين بانتظام على إجراءات مراقبة الجودة وأهمية الحفاظ على معايير عالية. إن الموظفين المدربين تدريباً جيداً أمر بالغ الأهمية لتنفيذ إجراءات مراقبة الجودة الفعالة والحفاظ عليها. يضمن التدريب المستمر تحديث الموظفين بأحدث تقنيات ومعايير مراقبة الجودة.

2. إقامة علاقات قوية مع الموردين

العمل عن كثب مع الموردين لضمان فهمهم لمتطلبات الجودة الخاصة بك وتلبيتها. يمكن أن يساعد بناء علاقات قوية في الحصول على مواد خام عالية الجودة باستمرار. ويمكن أن يؤدي التواصل والتعاون المنتظم مع الموردين إلى تحسين مراقبة الجودة من المصدر.

3. الاستفادة من التكنولوجيا

الاستفادة من التكنولوجيا لمراقبة الجودة، مثل معدات الاختبار الآلي والبرمجيات لتتبع مقاييس الجودة. يمكن للتكنولوجيا أن تعزز دقة وكفاءة عمليات مراقبة الجودة، مما يتيح الرصد في الوقت الحقيقي والاستجابة السريعة لأي مشاكل.

4. إجراء عمليات تدقيق منتظمة

قم بإجراء عمليات تدقيق منتظمة لمنشآتك وسلسلة التوريد لضمان الامتثال لمعايير الجودة. تساعد عمليات التدقيق في تحديد مجالات التحسين وضمان الالتزام المستمر ببروتوكولات الجودة. كما توفر عمليات التدقيق المنتظمة فرصة لمراجعة ممارسات مراقبة الجودة وتحديثها بما يتماشى مع التطورات في الصناعة.

5. مواكبة اتجاهات الصناعة

البقاء على اطلاع على اتجاهات الصناعة وأفضل الممارسات الناشئة في مجال مراقبة الجودة. التحسين المستمر هو مفتاح الحفاظ على الجودة العالية في سوق تنافسية. يمكن أن تساعد المشاركة في منتديات الصناعة وحضور ورش العمل والاشتراك في المنشورات ذات الصلة في البقاء على اطلاع بأحدث التطورات.

القائمة: أفضل الممارسات لمراقبة جودة الزنجبيل

- التدريب المنتظم: التأكد من أن الموظفين مدربون جيدًا على إجراءات مراقبة الجودة.

- علاقات قوية مع الموردين: التعاون مع الموردين للحفاظ على المواد الخام عالية الجودة.

- استخدام التكنولوجيا: تنفيذ أنظمة مؤتمتة لمراقبة الجودة بدقة وكفاءة.

- عمليات التدقيق المنتظمة: إجراء عمليات تدقيق متكررة لضمان الامتثال لمعايير الجودة.

- ابق على اطلاع مواكبة اتجاهات الصناعة وأفضل الممارسات.

الأسئلة الشائعة

1. ما أهمية مراقبة جودة الزنجبيل في عملي؟

تضمن مراقبة جودة الزنجبيل سلامة المنتج من خلال منع الملوثات مثل المبيدات الحشرية والمعادن الثقيلة ومسببات الأمراض. يفي الزنجبيل عالي الجودة بالمعايير التنظيمية، ويعزز سمعة العلامة التجارية، ويزيد من رضا العملاء، مما يؤدي في النهاية إلى نمو الأعمال التجارية.

2. كيف يمكنني اختيار موردي الزنجبيل عالي الجودة؟

لاختيار موردي الزنجبيل عالي الجودة، ابحث عن أولئك الذين يلتزمون بالممارسات الزراعية الجيدة (GAP)، مع وجود تاريخ ثابت للجودة، والاستعداد للخضوع لعمليات تدقيق منتظمة، والقدرة على تقديم شهادات وتقارير اختبار ذات صلة. إن بناء علاقات قوية يضمن جودة ثابتة للمواد الخام.

3. ما هي ممارسات التصنيع الجيدة (GMP) وكيف يتم تطبيقها في إنتاج الزنجبيل؟

ممارسات التصنيع الجيدة (GMP) هي مجموعة من الإجراءات والمبادئ التوجيهية التي تضمن اتساق المنتج وجودته. في إنتاج الزنجبيل، تشمل ممارسات التصنيع الجيدة الحفاظ على نظافة المرافق، والمناولة السليمة للمواد الخام، والتدريب الشامل للموظفين لتلبية المعايير العالية ومنع التلوث ومشاكل الجودة.

4. كيف يمكن للتكنولوجيا تحسين مراقبة جودة الزنجبيل؟

يمكن للتكنولوجيا تعزيز مراقبة جودة الزنجبيل من خلال معدات الاختبار الآلي وبرامج تتبع الجودة. وتوفر هذه الأدوات اختبارات أكثر دقة وكفاءة، ومراقبة في الوقت الحقيقي لمقاييس الجودة أثناء الإنتاج، والاستجابة السريعة للمشاكل المحتملة، مما يضمن جودة عالية للمنتج.

5. كيف يمكننا ضمان امتثال منتجاتنا من الزنجبيل للوائح والمعايير الدولية؟

ينطوي ضمان الامتثال للوائح والمعايير الدولية على إجراء اختبارات معملية منتظمة، والحصول على الشهادات ذات الصلة (مثل العضوية أو ISO 22000)، وإجراء عمليات تدقيق روتينية. إن فهم لوائح السوق المحددة والالتزام بها وتنفيذ نظام شامل لمراقبة الجودة يضمن استيفاء كل دفعة للمعايير المطلوبة.

لماذا تختار CAIE:

- التكامل الرأسي: لدى CAIE نموذج أعمال متكامل يغطي سلسلة التوريد بأكملها من الزراعة إلى التخزين والخدمات اللوجستية والتصدير. يسمح هذا التكامل الرأسي بتحسين مراقبة الجودة وإمكانية التتبع والكفاءة في جميع مراحل العملية.

- مزارع الزنجبيل المخصصة: تمتلك شركة CAIE أكثر من 10,000 فدان من المزارع في مدينة ويفانغ التي تعتبر موطن إنتاج الزنجبيل في الصين. ويضمن هذا الوصول المباشر إلى مناطق زراعة الزنجبيل الرئيسية إمدادات موثوقة وعالية الجودة من الزنجبيل الطازج.

- الالتزام بالمعايير الدولية: تتبع CAIE معايير دولية صارمة، بما في ذلك معايير الاتحاد الأوروبي واليابان والولايات المتحدة الأمريكية لتحليل التربة واختيار البذور وممارسات الزراعة والحصاد. ويضمن هذا الالتزام بالمعايير الصارمة منتجات الزنجبيل عالية الجودة.

- بنية تحتية حديثة: تمتلك شركة CAIE أكثر من 100,000 متر مربع من المستودعات الحديثة التي يتم التحكم في مناخها في مناطق إنتاج الزنجبيل، مما يضمن ظروف تخزين مثالية والحفاظ على جودة الزنجبيل من الحصاد إلى التصدير.

- الخبرة اللوجستية المستعبدة: لدى CAIE فريق لوجستي متخصص في الخدمات اللوجستية المستعبدة في منطقة التجارة الحرة في ويفانغ، مما يسهل عمليات التصدير السلسة والفعالة مع الحفاظ على جودة المنتج في جميع مراحل سلسلة التوريد.

- خبرة واسعة في التصدير: من خلال الاستحواذ على شركة Weifang Xinyide للعلوم والتكنولوجيا الزراعية المحدودة، اكتسبت شركة CAIE فريقًا محترفًا يتمتع بخبرة تزيد عن 20 عامًا في تصدير المنتجات الزراعية، بما في ذلك الزنجبيل.

- الدعم الحكومي: تستفيد شركة CAIE من دعم السياسات من الحكومات المحلية في مقاطعة شاندونغ ومدينة ويفانغ، مما يعزز ميزتها التنافسية في مجالات مثل الزراعة والتخزين والخدمات اللوجستية المستعبدة.

- الوصول العالمي: أقامت شركة CAIE علاقات مع أكثر من 30 من كبار المشترين من 19 دولة في جنوب شرق آسيا واليابان وأوروبا وأمريكا الشمالية، مما يدل على قدرتها على خدمة قاعدة عملاء عالمية متنوعة بفعالية.

- التنوع والحجم: بفضل مواردها وبنيتها التحتية الواسعة النطاق، يمكن لـ CAIE توفير كميات أكبر من مختلف أصناف الزنجبيل لتلبية الاحتياجات المتنوعة للمشترين في جميع أنحاء العالم.

من خلال اختيار CAIE كمورد للزنجبيل، يمكن للمشترين الاستفادة من سلسلة توريد موثوقة وعالية الجودة مدعومة بخبرة واسعة وبنية تحتية حديثة ودعم حكومي، مما يضمن تجربة توريد زنجبيل متسقة وفعالة.

اتصل ب CAIE اليوم ودعنا نكون مصدرك الموثوق للزنجبيل الصيني الممتاز.

- تريد معرفة المزيد عنّا

- تريد أن اتصل بنا مباشرةً.

- للمزيد من المعلومات مدونات الزنجبيل

- منتجات الزنجبيل CAIE