Ginger, a prized spice and medicinal root, holds a significant place in global trade and manufacturing. In B2B (business-to-business) manufacturing, ensuring the quality of ginger is paramount to maintain product integrity, consumer trust, and regulatory compliance. This article delves into the vital aspects of ginger quality control, offering insights and practical tips for businesses involved in its production and usage.

Why Ginger Quality Control is Essential in B2B Manufacturing

Health and Safety Concerns

Quality control ensures that ginger products are free from contaminants such as pesticides, heavy metals, and microbial pathogens. These contaminants can pose serious health risks to consumers, leading to potential legal and financial repercussions for businesses. Ensuring the safety of ginger products is critical to protect consumer health and maintain industry standards.

Regulatory Compliance

Ginger quality control is crucial for meeting regulatory standards set by food safety authorities. Compliance with these regulations not only ensures product safety but also enhances a company’s reputation and marketability. Regulatory bodies across different regions have stringent requirements that need to be met, and failing to comply can result in severe penalties, recalls, and loss of consumer trust.

Consumer Trust and Brand Reputation

High-quality ginger products build consumer trust and loyalty. Inconsistent or poor-quality products can damage a brand’s reputation, leading to lost sales and market share. Consumers expect consistency and reliability, and delivering high-quality ginger products consistently helps in establishing a strong brand identity and loyalty.

Economic Efficiency

Implementing effective quality control measures can reduce waste and increase production efficiency. By catching defects early, companies can avoid the costs associated with recalls and rework. Efficient quality control processes help in optimizing resource utilization, reducing operational costs, and improving overall productivity.

Key Components of Ginger Quality Control

1. Sourcing High-Quality Raw Material

The foundation of quality control starts with sourcing high-quality ginger. This involves selecting reputable suppliers who adhere to good agricultural practices (GAP) and ensuring that the raw ginger meets predefined quality standards. Working closely with suppliers to understand their farming practices and conducting regular audits can help in maintaining the quality of raw materials.

2. Implementing Good Manufacturing Practices (GMP)

GMP involves a set of procedures and guidelines to ensure products are consistently produced and controlled. It includes maintaining clean facilities, proper handling of raw materials, and thorough training of staff. Adhering to GMP helps in minimizing the risks of contamination and ensures the production of safe and high-quality ginger products.

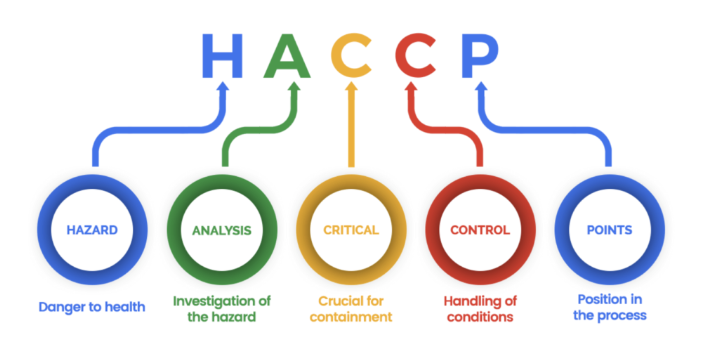

3. Hazard Analysis and Critical Control Points (HACCP)

HACCP is a systematic preventive approach to food safety. It identifies potential hazards and implements control measures at critical points in the production process. By focusing on prevention rather than end-product testing alone, HACCP helps in ensuring the safety and quality of ginger products throughout the production chain.

4. Regular Testing and Analysis

Regular testing of ginger for contaminants and quality attributes is essential. This includes microbiological testing, pesticide residue analysis, and testing for heavy metals. Implementing a robust testing protocol ensures that any potential issues are identified and addressed promptly, maintaining the safety and quality of the final product.

5. Certification and Compliance

Obtaining certifications such as organic, Fair Trade, and ISO 22000 can further assure quality and safety. These certifications require adherence to stringent standards and regular audits. They provide an additional layer of confidence for consumers and business partners, demonstrating a commitment to maintaining high-quality standards.

Quality Control Process in Ginger Manufacturing

Step-by-Step Quality Control Process

1. Raw Material Inspection

- Visual Inspection: Checking for mold, discoloration, and physical damage.

- Sampling: Taking samples for laboratory analysis to ensure the absence of contaminants and adherence to quality standards.

2. Cleaning and Drying

- Washing: Removing soil and impurities to prevent contamination and ensure product purity.

- Drying: Ensuring proper drying to prevent microbial growth and maintain the ginger’s quality and shelf life.

3. Sorting and Grading

- Sorting: Separating ginger based on size and quality to ensure consistency in the final product.

- Grading: Categorizing ginger into different grades based on quality standards, which helps in meeting specific market requirements.

4. Processing

- Cutting and Grinding: Depending on the end product requirements, ginger is processed into various forms such as slices, powders, or extracts.

- Packaging: Using food-grade materials to prevent contamination and preserve the ginger’s quality during storage and transportation.

5. Final Quality Check

- Laboratory Testing: Conducting final analysis to ensure compliance with quality standards and regulatory requirements.

- Batch Release: Approving the batch for sale if it meets all quality criteria, ensuring only high-quality products reach the market.

Table: Quality Control Checklist

| Stage | Quality Control Measure |

|---|---|

| Raw Material Inspection | Visual inspection, sampling for lab analysis |

| Cleaning and Drying | Washing, drying to prevent microbial growth |

| Sorting and Grading | Sorting by size, grading by quality |

| Processing | Cutting, grinding, packaging in food-grade materials |

| Final Quality Check | Laboratory testing, batch release approval |

Benefits of Effective Ginger Quality Control

Implementing robust quality control systems offers numerous benefits:

1. Enhanced Product Safety

Ensures that the ginger products are safe for consumption, reducing the risk of foodborne illnesses. By preventing contamination and ensuring high standards, businesses can confidently offer safe products to consumers.

2. Improved Customer Satisfaction

High-quality products lead to satisfied customers, fostering brand loyalty and repeat business. Satisfied customers are more likely to recommend the products to others, contributing to the growth of the business.

3. Regulatory Compliance

Helps in meeting local and international regulatory standards, avoiding legal issues and market access barriers. Compliance with regulations enhances a company’s credibility and facilitates smooth market operations.

4. Cost Efficiency

Reduces waste and rework, leading to cost savings and increased production efficiency. Efficient quality control processes help in minimizing losses and optimizing resource utilization, contributing to the overall profitability of the business.

5. Competitive Advantage

Certified and high-quality products can command premium prices, giving businesses a competitive edge in the market. High-quality standards differentiate a business from its competitors, attracting discerning clients and expanding market reach.

Tips for Maintaining High Ginger Quality in B2B Manufacturing

1. Invest in Training

Regularly train employees on quality control procedures and the importance of maintaining high standards. Well-trained staff are crucial for implementing and maintaining effective quality control measures. Continuous training ensures that employees are updated with the latest quality control techniques and standards.

2. Establish Strong Supplier Relationships

Work closely with suppliers to ensure they understand and meet your quality requirements. Building strong relationships can help in sourcing high-quality raw materials consistently. Regular communication and collaboration with suppliers can lead to better quality control at the source.

3. Utilize Technology

Leverage technology for quality control, such as automated testing equipment and software for tracking quality metrics. Technology can enhance the accuracy and efficiency of quality control processes, enabling real-time monitoring and quick response to any issues.

4. Conduct Regular Audits

Perform regular audits of your facilities and supply chain to ensure compliance with quality standards. Audits help identify areas for improvement and ensure ongoing adherence to quality protocols. Regular audits also provide an opportunity to review and update quality control practices in line with industry advancements.

5. Keep Up with Industry Trends

Stay informed about industry trends and emerging best practices in quality control. Continuous improvement is key to maintaining high quality in a competitive market. Participating in industry forums, attending workshops, and subscribing to relevant publications can help in staying updated with the latest developments.

List: Best Practices for Ginger Quality Control

- Regular Training: Ensure staff are well-trained in quality control procedures.

- Strong Supplier Relationships: Collaborate with suppliers to maintain high-quality raw materials.

- Use of Technology: Implement automated systems for accurate and efficient quality control.

- Regular Audits: Conduct frequent audits to ensure compliance with quality standards.

- Stay Updated: Keep up with industry trends and best practices.

FAQ

1. Why is ginger quality control crucial for my business?

Ginger quality control ensures product safety by preventing contaminants like pesticides, heavy metals, and pathogens. High-quality ginger meets regulatory standards, enhances brand reputation, and increases customer satisfaction, ultimately driving business growth.

2. How can I select high-quality ginger suppliers?

To select high-quality ginger suppliers, look for those adhering to Good Agricultural Practices (GAP), with a consistent quality history, willingness to undergo regular audits, and ability to provide relevant certifications and test reports. Building strong relationships ensures consistent quality of raw materials.

3. What are Good Manufacturing Practices (GMP) and how are they implemented in ginger production?

Good Manufacturing Practices (GMP) are a set of procedures and guidelines ensuring product consistency and quality. In ginger production, GMP includes maintaining clean facilities, proper handling of raw materials, and comprehensive staff training to meet high standards and prevent contamination and quality issues.

4. How can technology improve ginger quality control?

Technology can enhance ginger quality control through automated testing equipment and quality tracking software. These tools provide more accurate and efficient testing, real-time monitoring of quality metrics during production, and quick response to potential issues, ensuring high product quality.

5. How can we ensure our ginger products comply with international regulations and standards?

Ensuring compliance with international regulations and standards involves regular laboratory testing, obtaining relevant certifications (such as organic or ISO 22000), and conducting routine audits. Understanding and adhering to specific market regulations and implementing a comprehensive quality control system ensure each batch meets the required standards.

Why choose CAIE:

- Vertical Integration: CAIE has an integrated business model covering the entire supply chain from farming to warehousing, logistics, and export. This vertical integration allows for better quality control, traceability, and efficiency throughout the process.

- Dedicated Ginger Farms: CAIE owns over 10,000 acres of farms in Weifang City, which is considered the home of ginger production in China. This direct access to prime ginger growing regions ensures a reliable and high-quality supply of fresh ginger.

- Adherence to International Standards: CAIE follows stringent international standards, including those of the European Union, Japan, and the United States, for soil analysis, seed selection, planting, and harvesting practices. This commitment to rigorous standards guarantees top-quality ginger products.

- Modern Infrastructure: CAIE has over 100,000 square meters of modern, climate-controlled warehouses in the ginger production regions, ensuring optimal storage conditions and preservation of ginger quality from harvest to export.

- Bonded Logistics Expertise: CAIE has a specialized bonded logistics team in the Weifang Free Trade Zone, facilitating smooth and efficient export processes while maintaining product quality throughout the supply chain.

- Extensive Export Experience: Through the acquisition of Weifang Xinyide Agriculture Science and Technology Co., Ltd., CAIE has gained a professional team with over 20 years of experience in exporting agricultural products, including ginger.

- Government Support: CAIE benefits from policy support from the local governments of Shandong Province and Weifang City, which enhances its competitive advantage in areas such as planting, warehousing, and bonded logistics.

- Global Reach: CAIE has established relationships with over 30 large-scale buyers from 19 countries across Southeast Asia, Japan, Europe, and North America, demonstrating its ability to serve a diverse global customer base effectively.

- Variety and Volume: With its extensive resources and infrastructure, CAIE can provide larger quantities of various ginger varieties to meet the diverse needs of buyers worldwide.

By choosing CAIE as their ginger supplier, buyers can benefit from a reliable, high-quality supply chain backed by extensive expertise, modern infrastructure, and government support, ensuring a consistent and efficient ginger sourcing experience.

Contact CAIE today and let us be your trusted source for premium Chinese ginger.

- Want to know more about us.

- Want To contact us directly.

- For more ginger blogs

- CAIE Ginger Products